Bowhunters are obsessed with broadheads! They carry the same power to spur debate as Ford vs. Chevy. Spend 10 minutes on Google searching broadheads and you will find a seemingly endless list of articles, chats and posts telling you which heads are best, penetrate deeper, fly straighter and kill elk more surely and quickly. And, of course, you’ll find out which heads are the spawn of Satan because someone lost a deer.

I too am a broadhead fanatic and look forward to testing them each year. Broadheads are made to slice like a surgeon’s scalpel while busting their way through hide and bone. They need to be both precise and tough, which is exactly what makes them so intriguing. A quick look at advertisements will reveal the use of advanced materials, special blade designs, unique blade-retention systems and a wide range of cutting diameters and tip configurations. Some models are simple, having a true one-piece construction and typical 3-blade design, while others are much more complex, with sophisticated blade-retention systems.

One thing I have learned when it comes to broadheads is to let the testing do the talking, as it is easy to get caught up in hype and exaggerated claims. That is what we do here at Petersen’s BOWHUNTING; we employ a rigorous testing regimen, placing every broadhead on the same playing field and letting the chips fall where they may. Like a razor-sharp blade, we cut through the advertising, personal biases and wishful thinking to bring you unadulterated test results. We publish them as they are — no filters, no changes, no bull!

For 2016, we alternated back to mechanical heads after a fun and informative test of fixed-blade models in 2015. This year’s roster of 11 competitors includes some really interesting designs. For instance, there are two models — the Muzzy Trocar HB and BloodSport Gravedigger — from among a growing group of broadheads known as hybrids. That is, they have both fixed and mechanical blades designed to give you the best of both worlds. Another unique head in this year’s test is the Innerloc Shape Shifter, which employs a fieldpoint-shaped plastic case that surrounds the broadhead until impact when it breaks apart and gets out of the way. This design produced a great, slow-motion video explosion in our Zero-Penetration Test! We have first-time participants, such as Xecutioner and Swhacker, and manufacturers that have been involved since the beginning of our broadhead series such as Wasp and Grim Reaper. There is the rear-deploy group with NAP, G5 and Rage. And let’s not forget the Wac’Em, which boasts a 2.2-inch cutting diameter.

Test Philosophy

Our goal is to objectively test a series of performance characteristics that are critical to the successful completion of a broadhead’s mission. Tests are conducted with materials and processes that result in accurate, unbiased results. We build on our experiences year after year and continuously look to make enhancements that will improve our tests and provide more valuable information to bowhunters.

In an effort to generate the most authoritative broadhead-testing data anywhere, we employ an array of high-tech tools. For example, we use the Velocitip system from Full Flight Technology to gather in-flight drag and retained energy data. Accuracy is measured via the Petersen’s BOWHUNTING X-Ring Machine, which is advanced far beyond any commercially available shooting machine. And to create slow-motion video of the broadheads in action — from slicing through sheet metal to crashing into solid rock — we used an Olympus i-SPEED 3 high-speed video camera.

Where we did not have the in-house resources to conduct our tests, we sourced world-class testing services from the outside. For example, sharpness testing for all our broadhead blades was conducted on a state-of-the-art machine at the Cutlery & Allied Trades Research Association in Sheffield, England. Yes, we shipped the blades across the Atlantic Ocean to get the best sharpness results you’ll find anywhere!

Tests & Results

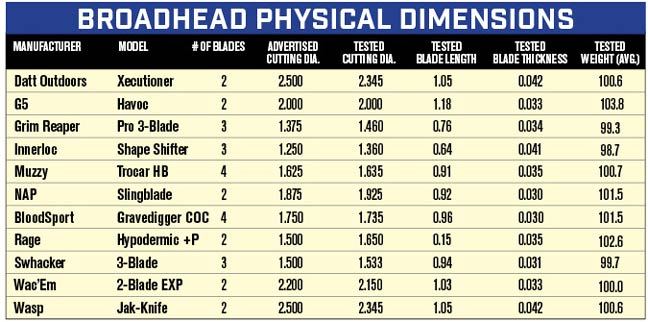

Physical Dimensions: A Mitutoyo 8-inch dial caliper was used to determine the size of each broadhead’s cutting diameter, blade length, blade thickness and the length of the head beyond the end of the arrow. Cutting diameter on 3-blade heads was calculated by laying two of the blade tips along one jaw of the calipers and the third on the opposite jaw. That number is divided by 1.5, and then multiplied by 2. Example: Greatest distance is .75/1.5=.5×2=1-inch cutting diameter.

An Easton Digital Grain Scale, calibrated according to manufacturer’s instructions, was used to determine the mass weight of each individual broadhead. Three separate heads were measured and averaged for a final result.

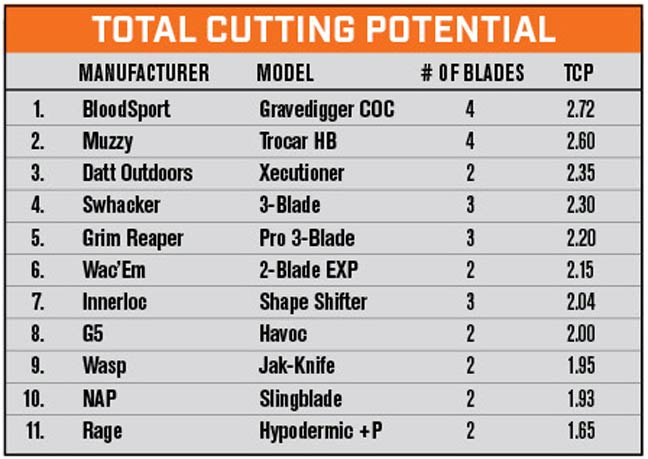

Total Cutting Potential: The ability of a head to cut — and the amount of cutting that actually occurs — is a factor of sharpness, cutting diameter and number of blades. With this in mind, we calculate the Total Cutting Potential (TCP) of a head by multiplying the radius by the number of blades. We consider it “potential,” because a lost blade in bone or otherwise means you have that much less to do the cutting once the head breaks through into the core of the animal. Blade angle is not considered in the TCP, since angle does not change the amount of flesh that is cut, as long as penetration is equal.

Here are two examples of TCP calculations: A 2-blade, 2-inch cutting diameter head has a radius of 1 inch. To get the TCP you multiply the radius by the number of blades, which gives you a TCP of 2 inches. Now, consider a 3 blade head with a cutting diameter of 1.375 inches. The radius is .6875-inch, so you multiply .6875 by the number of blades, 3. Your TCP would be 2.0625 inches, which means you will cut slightly more than the 2-blade head with a 2-inch cutting diameter.

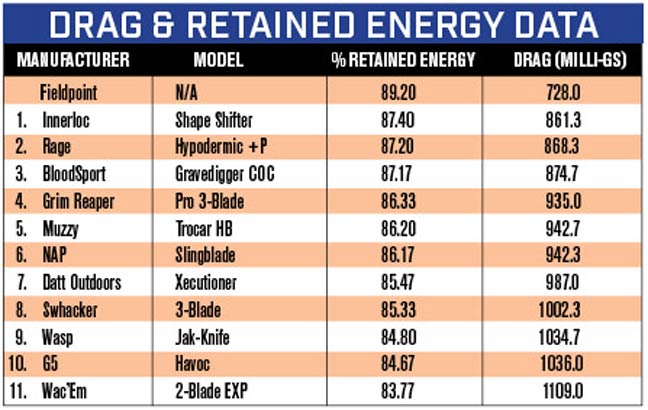

Drag & Retained Energy: The Velocitip system, which features an electronic arrow adaptor with built-in accelerometer, was used to compare the flight performance of various broadheads. The primary data collected from the system was drag (a direct measure of aerodynamic performance) and retained energy (how much lethality the arrow retains).

Since the exact same arrow was used for each shot, we can eliminate the drag created by the vanes. So, the differences you see in our results represent a direct comparison of one head to another. We also included fieldpoint data to provide a benchmark for performance.

…